The $165 Billion Gamble: Inside TSMC’s Audacious Plan to Build a Six-Fab Semiconductor Fortress in the Arizona Desert

An in-depth analysis of the strategic imperatives, immense costs, and operational frictions behind America’s bid for chip supremacy.

In the arid landscape of North Phoenix, a project of unprecedented scale and strategic importance is taking shape. Taiwan Semiconductor Manufacturing Company’s (TSMC) Arizona expansion has evolved from a significant foreign investment into a monumental, multi-generational effort to re-shore the world’s most critical manufacturing process.

With total committed investment soaring to a staggering $165 billion for a planned six-fabrication plant cluster, complete with advanced packaging facilities and an R&D center, this is no longer just about building a factory; it’s an attempt to transplant an entire technological ecosystem. This initiative, underwritten by billions in U.S. CHIPS and Science Act funding, represents a geopolitical gambit of the highest order. The central thesis of this briefing is that while the strategic necessity of this project is undeniable for U.S. technological sovereignty, the immense operational, financial, and cultural frictions TSMC is encountering reveal a fundamental disconnect between political ambition and manufacturing reality. The success or failure of this venture will not only determine the future of the global semiconductor supply chain but will also serve as a defining case study in the great power competition of the 21st century.

The Grand Strategy: From a Single Fab to a Self-Sustaining Fortress

The initial 2020 announcement of a $12 billion single fab has been dwarfed by a tidal wave of escalating commitments. The vision now articulated by TSMC Chairman C.C. Wei is not merely an offshore production site, but a self-sustaining “megafab” cluster intended to anchor a domestic U.S. semiconductor ecosystem. This dramatic expansion is a direct response to two powerful forces: immense demand from U.S. tech giants like Apple, NVIDIA, and AMD for onshore, cutting-edge manufacturing, and powerful geopolitical tailwinds from Washington aimed at de-risking the supply chain from its heavy concentration in Taiwan.

An Unprecedented Investment Escalation

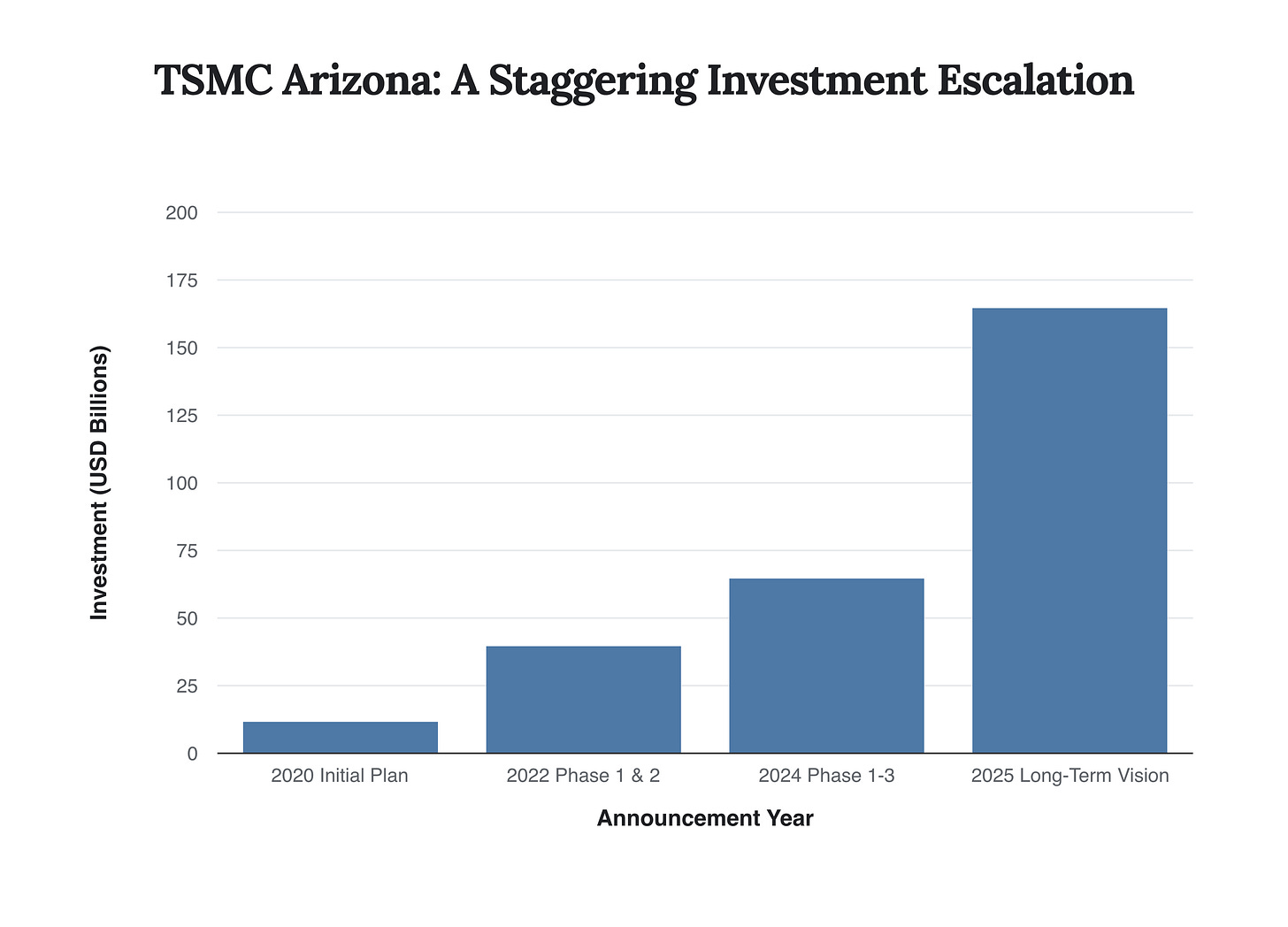

The project’s scope has expanded at a breathtaking pace. The initial plan for one fab has morphed into a three-fab, $65 billion initial phase, which has now been eclipsed by a longer-term vision for six fabs, two advanced packaging plants, and an R&D center, pushing the total investment envelope to $165 billion. This makes it the largest foreign direct investment in a greenfield project in U.S. history. The U.S. government has backed this with significant public funds, finalizing a deal for up to $6.6 billion in direct CHIPS Act funding, supplemented by up to $5 billion in low-cost government loans.

This chart illustrates the dramatic and rapid escalation of TSMC’s planned investment in its Arizona facilities, reflecting a deepening strategic commitment from both the company and the U.S. government.

Accelerating the Technology Roadmap

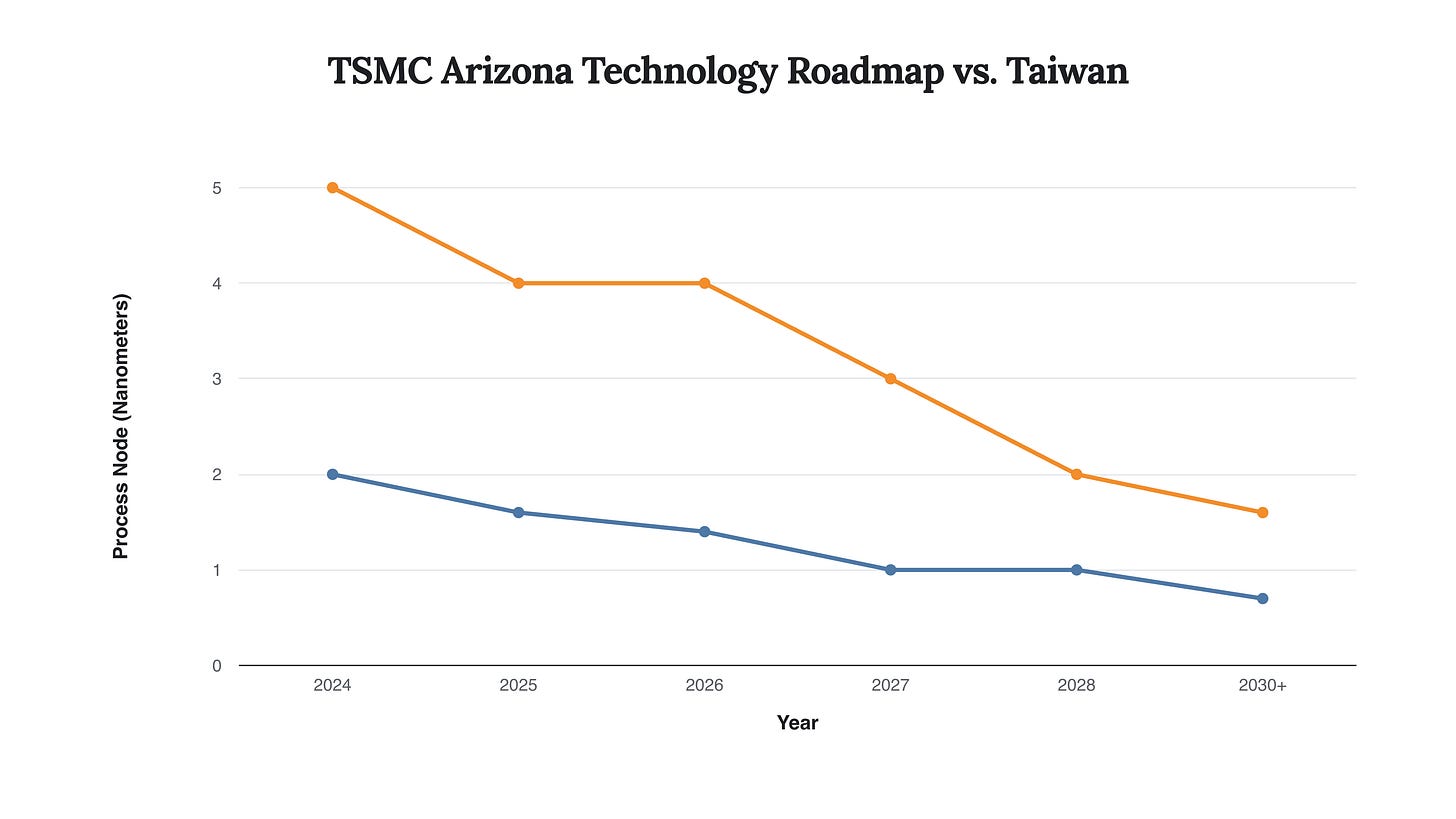

Initially, there was concern the Arizona fab would lag several generations behind Taiwan. However, intense customer demand, particularly for AI accelerators, has forced an acceleration of the technology roadmap. Fab 1 began producing 4-nanometer (N4) chips in 2025. Fab 2, with production now slated for 2028, will produce 3nm and the highly advanced 2nm nanosheet-transistor chips. Most significantly, the third fab, with groundbreaking in mid-2025, is targeted for the 2nm process and TSMC’s most advanced A16 (1.6nm-class) node by the end of the decade. TSMC has stated that once complete, the Arizona cluster could account for 30% of its total 2nm and more advanced chip capacity.

This chart visualizes the planned technology gap between TSMC’s fabs in Taiwan and the new Arizona facilities. While a gap remains, the plan to introduce 2nm and A16 processes demonstrates a significant acceleration for the U.S. site.

The Harsh Realities: A Collision of Cultures and Costs

Despite the grand strategic vision and accelerated plans, the execution of the Arizona project has been fraught with challenges that serve as a stark reality check on the complexities of reshoring advanced manufacturing. These issues span costs, labor, and regulatory environments, exposing the deeply ingrained efficiencies of TSMC’s Taiwanese ecosystem that are proving difficult—and expensive—to replicate.

“We are now entering a critical phase of handling and installing the most advanced and dedicated equipment. However, we are encountering certain challenges as there is an insufficient number of skilled workers with the specialized expertise required for equipment installation in a semiconductor-grade facility.”

The ‘Made in America’ Premium

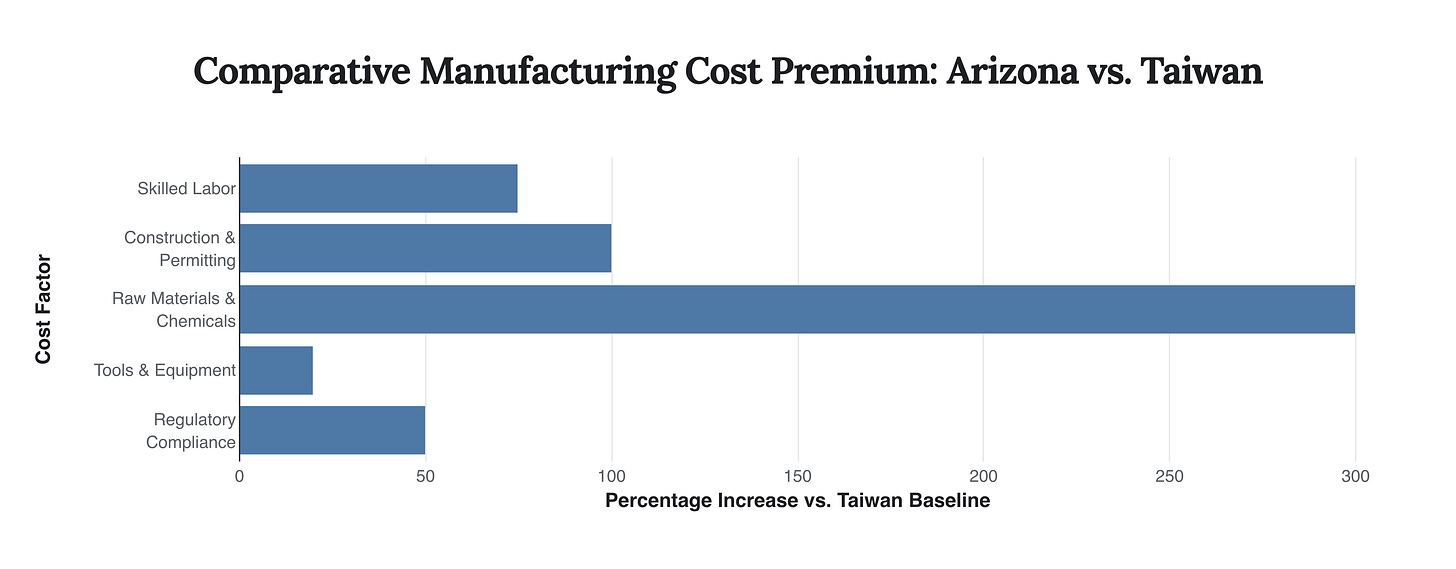

The cost of building and operating in the U.S. is substantially higher than in Taiwan. TSMC’s founder, Morris Chang, famously warned that U.S. manufacturing costs could be 50% to 100% higher; reports from the ground suggest this was not an exaggeration. The Arizona facility incurred a reported loss of over $440 million in 2024 alone. Higher labor costs, regulatory compliance—TSMC reportedly spent $35 million developing 18,000 rules to navigate local requirements—and a nascent local supply chain contribute to this premium. For example, the cost of ultra-pure sulfuric acid, a critical chemical, is reportedly five times higher in the U.S., forcing TSMC to ship it from Taiwan.

This chart breaks down the key drivers of the significant cost premium for semiconductor manufacturing in Arizona compared to TSMC’s established ecosystem in Taiwan. The disparities in supply chain and construction are particularly stark.

Labor Pains and Cultural Divides

One of the most significant hurdles has been the shortage of skilled labor required for sophisticated fab construction and tool installation. This led to initial production delays, pushing the start of Fab 1 from 2024 to 2025. The issue became a flashpoint when TSMC sought to bring in hundreds of experienced technicians from Taiwan, sparking opposition from local construction unions who argued it undermined the CHIPS Act’s job-creation goals. After months of negotiations, TSMC and the Arizona Building and Construction Trades Council reached an agreement in late 2023 to partner on workforce training and safety, resolving a major dispute. The episode highlighted a cultural and operational gap between TSMC’s high-speed, demanding construction standards and U.S. labor practices.

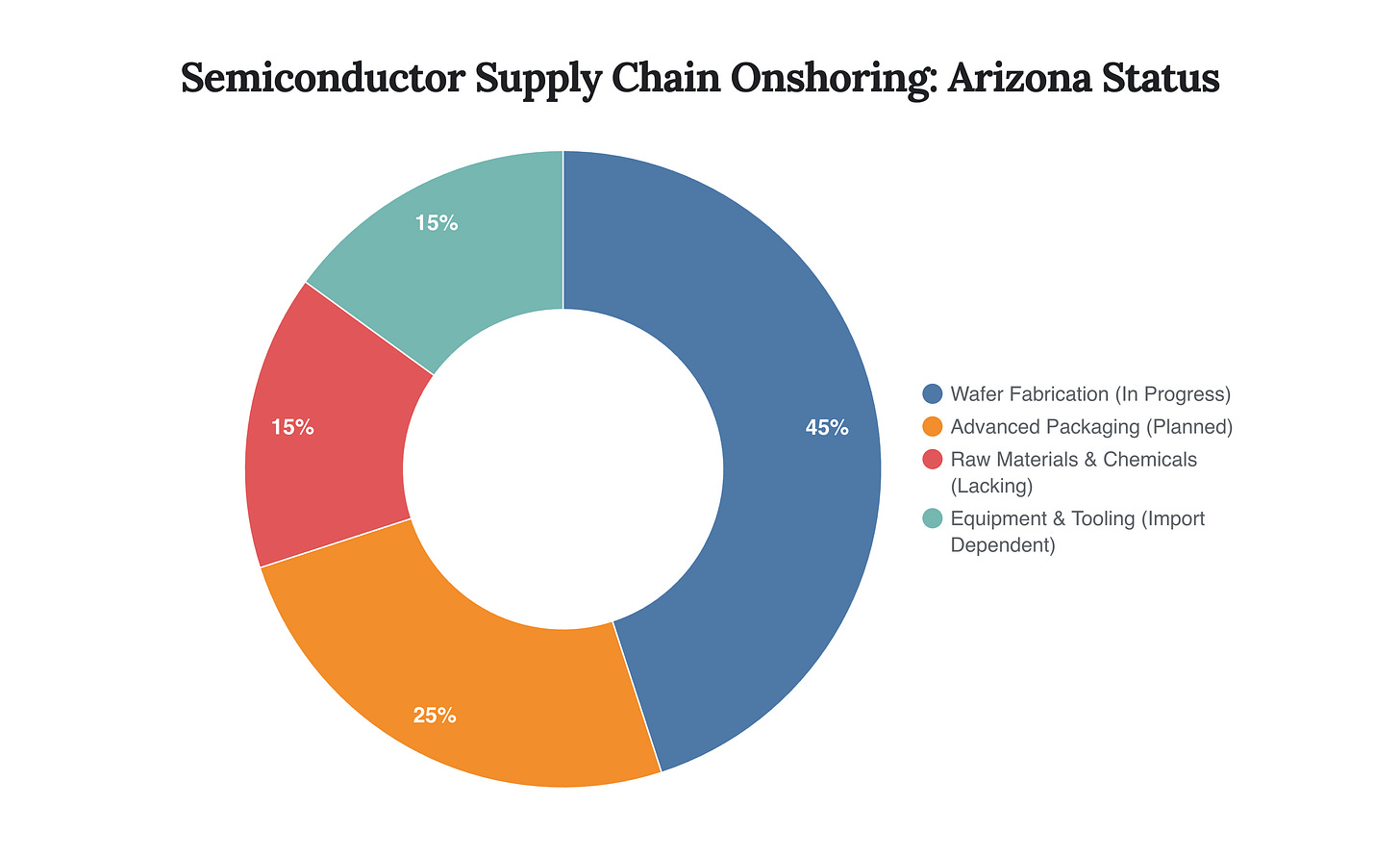

The Missing Ecosystem: Packaging and Supply Chain Gaps

A critical vulnerability in the U.S. semiconductor strategy is the near-total absence of advanced packaging capabilities. Chips fabricated in Arizona, including those for NVIDIA, must still be shipped back to Taiwan for the final, complex packaging steps like CoWoS (Chip-on-Wafer-on-Substrate). Recognizing this, TSMC’s expanded plan includes two IC assembly plants. Furthermore, TSMC is partnering with Amkor Technology, which is building its own advanced packaging facility in Arizona, scheduled to open in 2028. This race to build out the back-end of the supply chain is critical; without it, the Arizona fabs remain a high-tech island, dependent on trans-Pacific logistics for completion.

This chart provides a qualitative assessment of the maturity of the domestic semiconductor ecosystem in Arizona. While fabrication is well underway, critical gaps in packaging and the local supply chain remain significant challenges.

Strategic Foresight: Winners, Losers, and Future Scenarios

The monumental effort in Arizona is re-shaping the global technology landscape, creating clear winners and losers and setting the stage for several potential future scenarios. The ultimate outcome hinges on whether the operational challenges can be overcome to realize the immense strategic and economic goals.

The Winners

U.S. National Security & Tech Sovereignty: The primary winner. Onshoring the production of 4nm, 3nm, 2nm, and eventually A16 chips drastically reduces reliance on a geopolitically vulnerable region for the hardware that powers everything from AI data centers to advanced military platforms.

U.S. Fabless Chip Designers (Apple, NVIDIA, AMD): These companies gain a resilient, onshore supply chain for their most advanced products, mitigating geopolitical risk and potentially shortening logistics lines. They will, however, likely face higher costs.

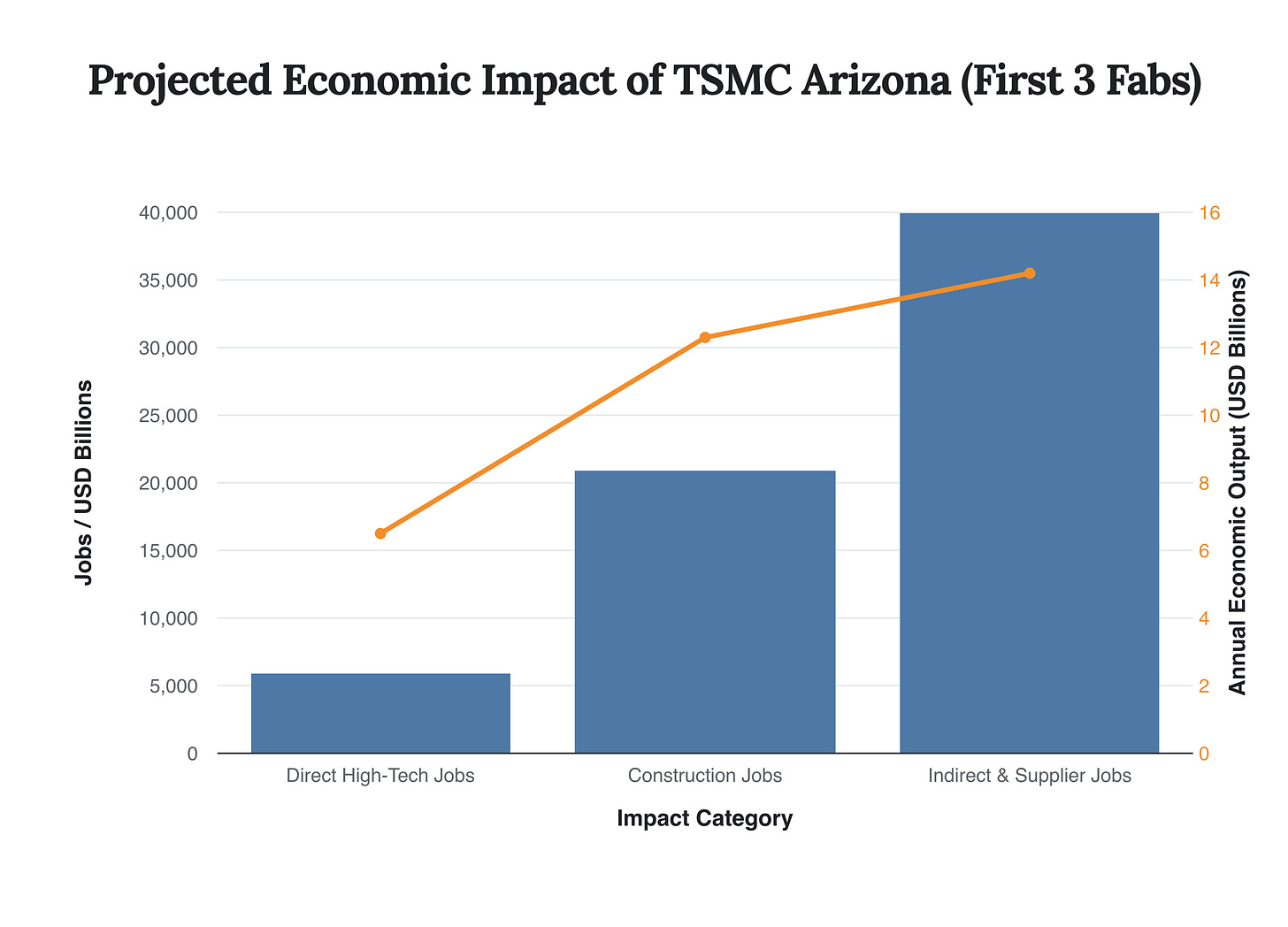

The State of Arizona: The influx of over $165 billion in investment, creating an estimated 6,000 direct high-tech jobs and over 60,000 construction and indirect jobs, is transformative for the regional economy, cementing it as a premier global semiconductor hub.

The Losers

Globalized Supply Chain Efficiency: For decades, the semiconductor industry has optimized for cost and efficiency, leading to extreme geographic specialization. The move to a more resilient, regionalized model introduces redundancies and higher costs, which will ultimately be borne by consumers in the form of more expensive electronics.

TSMC’s Profit Margins: While subsidies help, the higher operational costs in the U.S. will inevitably pressure TSMC’s industry-leading margins. The company is making a strategic trade-off, prioritizing geopolitical stability and customer relationships over pure financial optimization. However, its Arizona subsidiary did report its first profit in H1 2025, suggesting the subsidy model can be effective.

This chart visualizes the projected job creation and economic output stemming from the first phase ($65B) of TSMC’s Arizona investment, highlighting the significant local economic benefits.

Future Scenarios to Monitor

The Best Case: ‘Silicon Desert’ Realized. Buoyed by CHIPS Act funding and strong partnerships, TSMC masters its U.S. operations. The full six-fab cluster and packaging plants are completed ahead of schedule, attracting a mature local supply chain and creating a resilient, cutting-edge ecosystem. U.S. tech leadership in AI and high-performance computing is secured for a generation.

The Base Case: Muddling Through. The project continues to face intermittent delays and cost overruns. The fabs achieve volume production but consistently operate at a higher cost base than their Taiwanese counterparts. The U.S. achieves a significant degree of chip security, but the “Made in America” premium remains a persistent drag on the tech economy.

The Worst Case: The Quagmire. Persistent labor issues, intractable supply chain gaps, and political shifts in Washington that reduce long-term subsidies lead TSMC to curtail its most ambitious expansion plans. The initial fabs operate, but the grand vision of a self-sustaining cluster fails to materialize, leaving the U.S. with a hugely expensive but incomplete solution to its supply chain vulnerability.

The trajectory of the TSMC Arizona expansion is the single most important signpost for the future of global technology manufacturing. The recent acceleration in investment and technology roadmaps, despite the well-documented struggles, indicates a powerful commitment to see this through. However, the path is far from smooth. The ability to close the gap between the blueprint and the reality on the ground will define the next decade of technological and geopolitical competition.